The way to Make Concrete Molds (DIY Concrete Paver Mold Ideas)

작성자 정보

- Teddy Batman 작성

- 작성일

본문

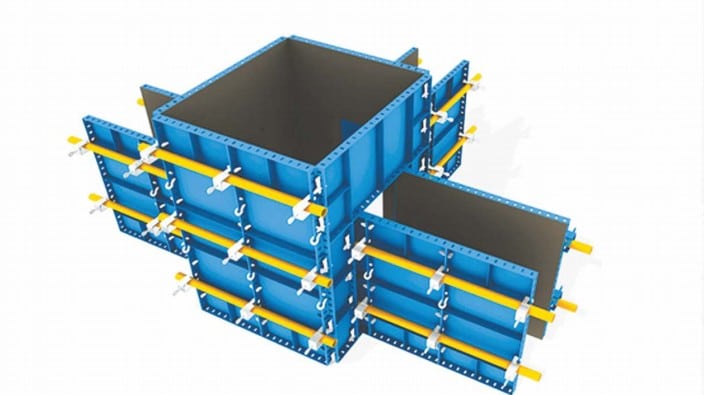

Comply with these step-by-step instructions to make your individual unique stepping stones with ease and precision. Elevate the charm of your backyard with delightful and unique do-it-your self rhubarb leaf stepping stones! Using a easy concrete mold, you can vogue a natural, leaf-patterned pathway that seamlessly integrates together with your out of doors house, making a whimsical touch that enhances the overall aesthetic. Aluminum molds for injection molding are liable to flash. Aluminum is a soft metallic and is due to this fact simpler to deform and قالب فلزی بتن permit the injected material to leak out of the machined cavity. Steel is a tougher materials, which reduces the prospect for flash. Steel molds will not deform as simply as an aluminum mold. Avoiding these common errors can increase your probabilities of making a successful and durable concrete mold. Insufficiently getting ready the mold: Earlier than pouring the concrete, it is essential to properly clear and coat the inside of the mold with a release agent or oil to stop the concrete from sticking. Utilizing the improper type of concrete combine: Different tasks require different types. Make certain to decide on the appropriate combine in your specific mold and utility.

As a result of handbook operations, the cycle time per casting will be longer. Nonetheless, the straightforward construction of the machine makes casting extra reasonably priced. Gravity die casting provides higher grain construction, surface end, geometrical accuracy, mechanical properties, and fewer casting defects when compared to sand casting. Nonetheless, metallic dies are expensive and won't be suitable for intricate shapes.

I’m going to introduce you to the fundamental elements of molding. Understanding the fundamentals is essential, whether you’re a DIY enthusiast or knowledgeable craftsman. The process begins with a model of your desired shape. This mannequin can be something from a easy block to a fancy sculpture. To create one, you should cover your model in a mold-making material. Properly, you may make your personal concrete mold by replicating any object to make it into a cement planter. It can be a challenge to think about find out how to make your individual silicone mold for a cement planter- or for anything, because you've to think about the positive and destructive space in reverse. This progress usually occurs in damp or shaded areas that do not receive a lot of sun or heat. Concrete, with all its nooks, crannies and pores, is definitely an incredible incubator for mold. Wet, humid weather with heat temperatures solely improves the growing circumstances. What does mold on concrete look like?

Moreover, I’ve made a video tutorial so that you don’t miss a single step. But make sure you also learn and watch because some issues are easier to elucidate in writing, whereas other parts are simpler to show in a video. Please click the button to subscribe to my YouTube channel and be notified when I've a new video tutorial! Find out how to know what are the perfect concrete silicone molds, and discover the place to purchase them from. You could also be looking to buy a reusable concrete silicone mold, especially in case you are planning on promoting concrete and cement planters or different concrete crafts. Wouldn’t it be a lot easier to seek out the best concrete mold, if somebody had already executed the research? Concrete makes up the world round us. Fashionable skyscrapers, highways, and parking lots wouldn’t be the same with out this ubiquitous material, however how do contractors form and mold the concrete how they need it? Concrete has been round for a very long time, however the strategies used to form, pour, and mold concrete aren’t too completely different from yesterday’s strategies. When you see a leak, then use oil-primarily based clay to plug it. To take away the concrete silicone mold from the type, use a utility knife to chop via the taped areas and between the foam board pieces where it’s glued. To help with eradicating the sides, use a putty knife ( I couldn’t discover mine, but a wide chisel labored nice) to shimmy in between the mold and sides and pry the items apart. You most likely have a bit of lip where the silicone is overlaying the underside of the bowl. I trimmed this space to helpp make demolding easier, however your planter will look nicer you don’t.

To ensure that a concrete formwork to be suitable for a construction undertaking, it must be strong enough to hold the load of the concrete with out slipping, cracking, or bending. Any vital harm to the formwork will permit the concrete to pour out, or it may just destroy the meant shape if the concrete is partially cured. After you have these dimensions, measure and mark them onto the foam board and then lower the sides and base out. To cut these, use a T-sq. and a craft knife with the whittling blade. I discover it easiest to chop foam insulation boards by inserting the part I’m chopping in order that it overhangs my work table so I can freely slice via the foam. Tip: Make certain to hold the blade straight (perpendicular to the flooring) while you minimize. If it’s slightly angled, you’ll have a tricky time attaching the sides. Use hot glue (or a hundred% silicone caulk) to attach the sides to the bottom. Gluing it first will make it simpler to work with once you go to tape it.

관련자료

-

이전

-

다음